| Tweets by @TigerRearEnds | |

| January 22, 2012 | |

|

|

| Tiger Rear Ends Now Offering Revolutionary REM ® Isotropic Superfinish | |

|

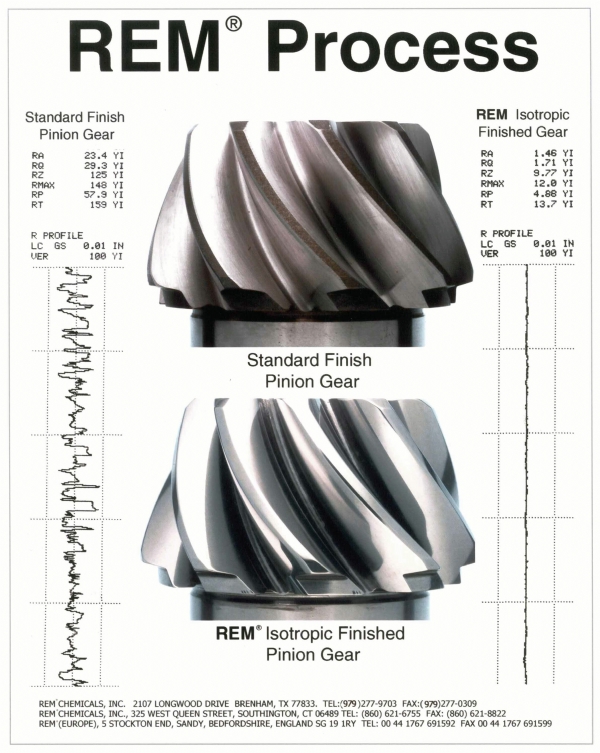

Are you looking to achieve a “winning” finish without destroying the functional shape of your components? Consider Tiger Rear Ends for all of your REM ® Isotropic Superfinish Process (ISF) needs! REM is an affordable and highly effective solution that has been proven to decrease drag and friction while increasing the efficiency, effective horsepower, durability, and extending component life. Studies have shown a 95% reduction in gear wear compared to non ISF® processed components. Applying this revolutionary process to motorsports applications result in faster and more efficient vehicles that win races as well as parts that last considerably longer than standard components. In addition to providing quality quick change rear ends, Tiger Rear Ends also offers the REM® ISF process for your motorsports related or non-related transmission, engine, quick change, or chassis components, including: · Hubs · Bearings · Races · Crank Shafts · Cam Shafts · Jackshaft · Ring and Pinion · Rods · Valve Springs · ….and More!

Sometimes referred to in the industry as REM® polishing, the procedure is really not a polishing process, but rather a finishing process. The ISF ® Process creates a smooth, micro textured surface that will withstand harsh conditions in motorsports, off-road, automotive, and other applications. The REM® procedure involves two steps. The first step, referred to as the "Refinement Process", involves a chemical interaction on the surface of the part. A soft, thin (one micron) film is formed on the surface of the part. The part then interacts with the ceramic media in a special vibratory bowl. During this interaction the film is physically removed from the "peaks" of the processed part and the "valleys" are unaffected. The chemically induced film re-forms only at the peaks that are interacting with the vibratory media, and the process repeats itself. Over time, the peaks are removed, leaving only the valleys, producing the improved micro finish. The second step is referred to as the "Burnish Process." After the required micro finish is achieved, a mild alkaline mixture is introduced. After a relatively short period a polished, chrome-like finish is produced. In addition to the polishing effects, this step effectively removes all traces of the film formation from the refinement process. Call Tiger Rear Ends today to receive a quote for all of

your REM® ISP needs at (704)603-4431. For more information about REM®

Isotropic Superfinish Process, visit www.tigerrearend.com or www.remchem.com on the World

Wide Web.

|

|